Commercial Chain Link Fence Installation Made Easy

- Jake Bunston

- Jul 17, 2025

- 8 min read

The Professional Approach to Commercial Fencing

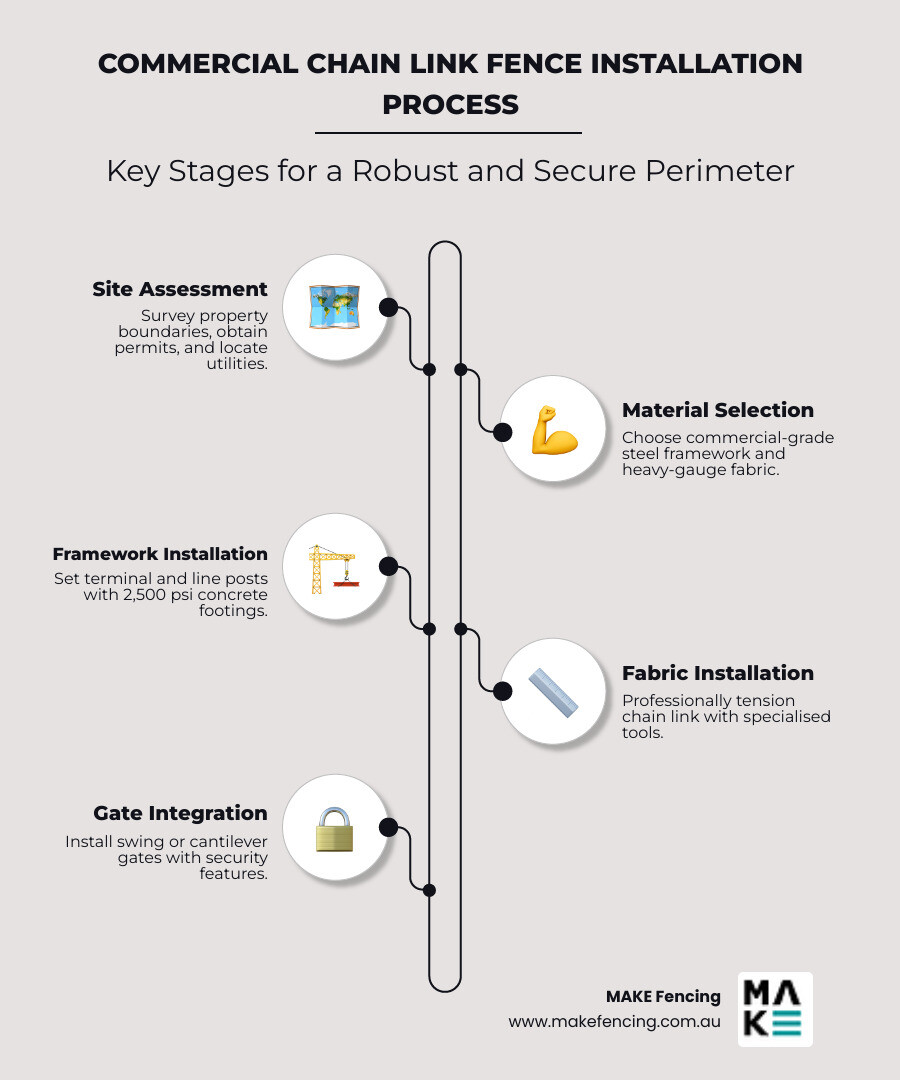

How to install commercial chain link fence requires specialised expertise, commercial-grade materials, and strict adherence to industry standards. The process involves five critical stages: meticulous site preparation and planning, selecting heavy-duty commercial materials, installing a robust framework with proper concrete footings, professionally tensioning the chain link fabric, and integrating gates with advanced security features.

Key Installation Steps:

Site Assessment - Survey property boundaries, obtain permits, and locate utilities

Material Selection - Choose commercial-grade steel framework and heavy-gauge fabric

Framework Installation - Set terminal and line posts with 2,500 psi concrete footings

Fabric Installation - Professionally tension chain link with specialised tools

Gate Integration - Install swing or cantilever gates with security features

Unlike residential installations, commercial chain link fencing demands heavier materials, deeper concrete footings, and compliance with stringent safety regulations. The average commercial installation in Melbourne typically ranges from $45 to $85 per linear metre, depending on height, gauge, and security requirements.

Why Professional Installation Matters

Commercial fencing isn't just about security - it's about creating a lasting perimeter that withstands Melbourne's demanding weather conditions while meeting council regulations. Poor installation can lead to sagging fabric, unstable posts, and costly repairs that disrupt business operations.

I'm Jake Bunston, founder of Make Fencing, and over the past decade, I've overseen hundreds of commercial chain link installations across Melbourne's diverse commercial landscape. My hands-on experience with how to install commercial chain link fence has taught me that proper technique and quality materials make the difference between a fence that lasts years versus one that needs constant maintenance.

The Professional Process: How to Install Commercial Chain Link Fence

When it comes to how to install commercial chain link fence, a properly engineered commercial installation is a complex process demanding professional expertise from start to finish. At MAKE Fencing, we've refined our approach over more than a decade, understanding that your business needs a fence that won't just look good on day one, but will stand strong for years to come.

Commercial chain link installation is a precise dance of engineering and craftsmanship. Each step builds upon the last, creating a security perimeter that's both robust and reliable. Let me walk you through exactly how we approach each stage of the process.

Step 1: Meticulous Planning and Site Preparation

Before we even think about digging the first hole, we spend considerable time getting to know your property. This isn't just about measuring distances – it's about understanding how your fence will interact with Melbourne's unique landscape and regulatory environment.

Our site survey process begins with a thorough examination of your property boundaries. We use professional surveying equipment to ensure absolute accuracy, because even a small error at this stage can create major headaches later. The terrain tells us a story about drainage, soil conditions, and potential challenges that might not be obvious to the untrained eye.

Melbourne council regulations can be surprisingly complex, varying significantly between suburbs. What's perfectly acceptable in one area might require special permits in another. Our team stays current with these ever-changing requirements, handling all permit acquisition so you don't have to steer the bureaucracy yourself.

Site clearing involves more than just removing obvious obstacles. We carefully grade the fence line to create optimal conditions for installation, paying special attention to drainage patterns that could affect your fence's longevity. A crucial first step is locating all underground utilities; we coordinate with Dial Before You Dig to mark every water, gas, and electrical line on your property. This isn't just about avoiding expensive repairs; it's about keeping our crew and your site safe.

The groundwork we do during this phase directly impacts every subsequent step. Proper preparation means fewer surprises, faster installation, and a fence that performs exactly as intended. More info about our Design, Plan, and Permits process shows how we handle these crucial early stages.

Step 2: Selecting Commercial-Grade Materials for Durability

The difference between residential and commercial chain link fencing isn't just about height – it's about engineering for entirely different performance standards. When we approach how to install commercial chain link fence, material selection becomes critical to long-term success.

Commercial-grade framework components are built to handle significantly greater stress than their residential counterparts. We're talking about pipe wall thickness that can withstand impact, weather extremes, and the constant use that commercial properties experience. Where residential projects might use lighter materials, we typically specify heavy-gauge fabric in 8 to 9-gauge wire, providing exceptional strength and resistance to cutting or climbing attempts.

Galvanised steel forms the backbone of our commercial installations. This isn't just a surface treatment – it's a comprehensive protection system that shields your investment from Melbourne's unpredictable weather patterns. The zinc coating we use adheres to strict ASTM standards, ensuring consistent performance whether your fence faces coastal salt air or urban pollution.

For properties with specific security requirements, we can customise fabric types to match your needs. Mini mesh provides tighter patterns that discourage climbing, while maintaining the visibility that many commercial properties require. The beauty of working with experienced professionals is that we can match materials precisely to your site's unique demands.

SS40 (Schedule 40) framework represents the gold standard for commercial and industrial applications. This heavy-duty construction provides superior durability that justifies the investment through reduced maintenance and extended lifespan. Learn more about our Metal Fencing Melbourne options to understand how material quality directly impacts your fence's performance.

Step 3: Framework and Post Installation for Lasting Stability

With materials selected and site prepared, the real engineering begins. Framework and post installation represents the foundation of your fence's long-term performance, and there's no room for shortcuts when it comes to how to install commercial chain link fence.

Terminal posts – those crucial end, corner, and gate posts – receive our most intensive attention. These anchors must support the entire fence system, so we dig holes approximately 8 inches in diameter and typically 30 inches deep, though we adjust depth based on local soil conditions and frost line requirements. In Melbourne's varied terrain, this might mean going deeper in clay soils or adjusting for rocky conditions.

Line posts are installed at intervals not exceeding 10 feet on centre, though we often reduce this spacing for fences with additional wind load factors. Each line post gets a 6-inch diameter hole, usually 18 to 24 inches deep, sized to provide adequate support without over-engineering the installation.

Concrete footings use high-quality concrete achieving 2,500 psi compressive strength after 28 days of curing. We crown the concrete around each post base, sloping away to shed water and prevent the pooling that can lead to premature deterioration. Plumb posts aren't just about appearance – they're essential for proper fabric tension and gate operation.

The top rail installation requires precision threading through loop caps on line posts and secure attachment to terminal posts using rail end cups and brace bands. We position all nuts on the inside of the fence, making them inaccessible from outside while ensuring proper structural integrity.

Our approach to post spacing and concrete work ensures your fence maintains its stability through years of Melbourne weather. See examples of our Commercial Fence Installation to understand the quality standards we maintain.

Step 4: Professional Fabric Installation and Tensioning

The tensioning process is a critical step that requires specialized tools and techniques to ensure a lasting result. Getting chain link fabric perfectly taut requires specialised knowledge, proper tools, and years of experience understanding how different materials behave under stress.

We begin by carefully unrolling the heavy-gauge fabric along the fence line's exterior. Professional stretching tools including heavy-duty stretcher bars and come-along winches allow us to achieve uniform tension across the entire fence run. This isn't about pulling as hard as possible – it's about finding that perfect balance where the fabric has slight give when squeezed by hand, indicating optimal tautness.

Tension bars threaded vertically through the first row of chain link diamonds create the anchor point at each terminal post. As we stretch the fabric, we also "dress" it, ensuring diamond patterns run true and eliminating any low spots that could compromise appearance or security.

Fence ties and hog rings secure the fabric to framework at strategic intervals – typically every 24 inches along the top rail and every 12 inches on line posts. This spacing ensures the fabric remains securely attached while allowing for natural thermal expansion and contraction.

We maintain ground clearance of 50mm to prevent small animals from accessing your property while ensuring proper drainage. The precision required for this process is why we invest in professional-grade equipment and ongoing training for our installation teams.

Step 5: Integrating Gates and Advanced Security Features

The final stage of how to install commercial chain link fence brings together functionality and security through carefully engineered access solutions. Gates aren't just openings in your fence – they're sophisticated systems that must operate smoothly while maintaining your perimeter's integrity.

Swing gates work well for pedestrian access and light vehicle traffic, available in single or double configurations depending on your operational needs. For high-traffic areas or space-constrained locations, cantilever slide gates offer smooth operation without requiring ground tracks that can collect debris or create maintenance issues.

Gate hardware selection focuses on commercial-grade components designed for frequent use. Heavy-duty hinges, robust latches, and properly sized gate posts prevent the sagging and operational problems that plague inferior installations. We ensure all hardware nuts are positioned on the fence's interior side, maintaining security while allowing for necessary maintenance access.

Automation systems integrate seamlessly with our gate designs, incorporating motors, sensors, and access control systems while maintaining compliance with safety compliance standards including ASTM F2200 and UL 325 requirements for electrically operated gates.

For improved security, we can incorporate barbed wire installations along the fence top, using angled arms that maximise deterrent effect while adhering to local safety regulations. These additions require careful planning to ensure they improve rather than compromise your fence's overall performance.

Our comprehensive approach ensures your commercial chain link fence becomes a complete security solution custom to your specific operational requirements. Explore our Security Fences for Commercial Properties to see how we can improve your property's protection.

Finalising Your Project and Ensuring Long-Term Performance

At MAKE Fencing, we understand that how to install commercial chain link fence isn't complete until every detail has been perfected and you're completely satisfied with the result. Our commitment to excellence extends well beyond the physical installation – it's about delivering a finished product that will serve your business reliably for years to come.

Final Touches and Quality Assurance

Once your fence framework, fabric, and gates are in place, our team shifts focus to the finishing touches that separate a good installation from an exceptional one. The first priority is a thorough site cleanup. We carefully remove all debris, excess materials, and tools, leaving your commercial property neat and professional. After all, a clean site reflects our respect for your business and our commitment to professionalism.

The heart of our quality assurance process is the comprehensive final inspection. Our project managers conduct a detailed review of every aspect of your installation, checking that fabric tension is optimal, all fastenings are secure, posts remain perfectly plumb, and gates operate smoothly. We verify that every element adheres to industry standards such as ASTM F567 for installation and CLFMI guidelines, as well as our own stringent quality benchmarks.

During this inspection, we confirm that concrete has achieved proper compressive strength, post spacing meets specifications, and fabric maintains the correct ground clearance. For sites requiring electrical grounding, we coordinate with licensed electrical contractors to ensure this critical safety requirement is met, though this typically falls outside our direct installation scope.

Perhaps the most important part of our process is the client walkthrough. This is your opportunity to inspect the completed project alongside our team, ask questions, and receive hands-on guidance for operating gates or any integrated security features. We want you to feel completely confident in your new security investment.

With over a decade of experience, MAKE Fencing ensures every detail meets the highest standards of quality and safety. Our approach combines proven expertise with attention to detail, making us a trusted partner for businesses across Melbourne. From our base in Bayswater to commercial sites throughout Victoria, we pride ourselves on delivering projects on time and within budget, ensuring minimal disruption to your daily operations.

The quality and precision we bring to every commercial chain link installation is evident in our track record. We encourage you to View Our Fencing Work Portfolio to see the diverse range of commercial projects we've completed, showcasing our proven expertise and meticulous attention to detail.

To ensure your commercial property is secured with a durable, compliant, and professionally installed fence, it is essential to partner with experienced installers. At MAKE Fencing, we're dedicated to providing high-quality, customisable fencing and gate solutions that deliver both robust security and visual appeal. Explore our commercial fencing solutions to get a custom quote for your project and experience the MAKE Fencing advantage for yourself.